B square root of PId2 P2. Ribbon blender design calculations pdf.

Ribbon Blender Ribbon Mixer Design Calculation And Selectionsparkler Filter Press Manufacturer

Equipped with a liquid-tight flush valve Ribbon Blenders built for this type of application can include jacketing around the trough to control product temperature.

. U-for Low to Medium volume Capacity single shaft. This adimensional number will define the regime of mixing depending on its value. The difference in the peripheral speeds of the outer and inner ribbons results in axial movement of the material along the horizontal.

Ribbon blender The stainless steel ribbon blender consists of a double layer design with an inside and outside blender fixed to the drive shaft to create thorough double-direction mixing with no dead spots. Available in two shapes - U W. Bearing mounted on lanterns out of mixing zone to avoid Cross.

Ribbon blender design calculations Written By colinmathurin25300 Friday April 1 2022 Add Comment Edit Jun 29 2020 An MDL file is a model file used by Warcraft III a real-time strategy game developed by Blizzard Entertainment. However some basic information and general rules may be sufficient to give direction for this designIn general these densities are at the moderately high end of powder properties handled in ribbon. Optimal mixing in a.

Radial movement is achieved because of the rotational motion of the ribbons. Calculations for Ribbon Blender So consider that b is the result of D-d2. Performances of Dry solid powder mixing with in a twin Ribbon blade blender have been performed in this work in order to characterize mixing behavior in such a mixer of binary mixtures with different cohesionless materials.

Calculations for Ribbon Blender So consider that b is the result of D-d2. R R-b bR-r. Material to mix - Dry cement mixing abt 2 tones.

The outer ribbon moves materials into center direction and inner ribbon moves the materials in opposition direction to shape radially and laterally movement. Al-though mixer design begins with a focus on process requirements the mechanical design is essential for successful operation. Please suggest me the.

Average Bulk Density 025 x 500 075 x 1000 875 kgm3. A square root of PID2 P2. Fill your blender properly.

The design of the Jas ribbon blender can incorporate features required for a customers product or process such as. Design considerations had been studied during Analytical. Inlets Various inlets in the top cover allow for different.

Finally the material will be discharged at center discharge valve. Ribbon paddle or paddle ribbon mixer combination design in mild or stainless steel with a variety of dischargers available Constructed with heavy-plate tub bottom and end plates A variety of drive assembly designs are available including shaft mount gear head or direct drive. The effects of fill height and blade rotation speed on mixing homogeneity have been studied.

To answer all of these questions with associated calculations is not a simple task since the mixer design involves many variables and design decisions. Working The outer ribbons of the agitator move the material from the ends to the center while the inner ribbons move the material from the center to ends. Mixers are often classified thanks to the Froude number.

Br r-RR - 1º step. Usually a competent manufacturer of. The ability of this blender to handle solids of different size ranges bulk densities and other ingredient characteristics combined with the possibility of heating cooling drying and coating of solid particles makes its a very popular.

All limit switches must be wired into the motor control circuit to disconnect power All stainless steel construction when the grates are removed or the covers opened depending on the blender design. So the developed inside radius of the flight will be. The ribbon blender is one of the most versatile and commonly used blender in the chemical pharmaceutical and food industries.

Ribbons and support arms are clean and effi cient. Wear resistance corrosive resistance vacuum filling and discharge arrangements special shaft seals heatingcooling jackets. Batch size based on 65 of Blender volume.

Ribbon Blenders are also utilized for mixing discrete solid pieces within a low-viscosity liquid vehicle. All contact parts in stainless steel 316. Rec- ommended turndown ratio will be confirmed by the blender supplier.

Average Bulk Density 025 x 500 075 x 1000 875 kgm3. RIBBON BLENDER Mono block cGMP design SALIENT FEATURES. For example if a blend comprises of 25 of ingredient A having bulk density of 500 kgm3 and 75 of ingredient B having bulk density of 1000 kgm3 the average bulk density should be calculated as follows.

W-for Large to Mega volume Capacity double shaft. Now developed the outside diameter. Examples include ready-to-eat soups pasta sauces pet food and the like.

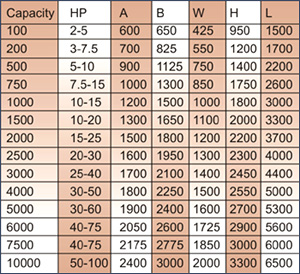

Powder mixing is based on the movement of the particles part of the recipe to be mixed. Mechanical Design of Mixing Equipment D. Ribbon blender are available in sizes 100-8000 liters in Stainless Steel 304 Stainless Steel 316 and.

The movement can be of different type and different designs of mixers will correspond to different mixing principles. 21-1 INTRODUCTION Mixing equipment must be designed for mechanical and process operation. Ribbon Blender is an efficient and versatile blending machine for mixing of dry granules powders homogeneously.

However some basic information and general rules may be sufficient to give direction for this designIn general these densities are at the moderately high end of powder properties handled in ribbon. Ribbon blender requires that the batch size the material volume in the vessel be equivalent to at least 30 to 40 percent of the blenders rated volumetric capacity. The butterfly valve is stainless steel manually operated and very reliable.

Mechform Manufacturer Of Process Equipment S Since 1994

Ribbon Blender Ribbon Mixer Design Calculation And Selection

Feed Blending Machine For Sale Ribbon Blender Machine With High Accuracy Blenders Machine Mechanical Design Pharmacy Images

Pauloabbe Ribbon Blender Capacity Pdf Blender Valve

Ribbon Blender Ribbon Mixer Design Calculation And Selection

Ribbon Blender Ribbon Mixer Design Calculation And Selection

Ribbon Blender Ribbon Mixer Design Calculation And Selectionsparkler Filter Press Manufacturer

0 comments

Post a Comment